Fuel Cell Technology IP Portfolio

- Intelligent Energy Limited is a leading fuel cell manufacturer with 30 years of experience in research, development & manufacture of zero-emission hydrogen fuel cell power systems.

- Headquartered in Loughborough, UK, Company produces the highest power density fuel cells ranging from 800W to 300kW+ for applications such as UAVs, automotive, aerospace, power systems, telecom, marine, rail and material handling.

For more details about technology: Click Here

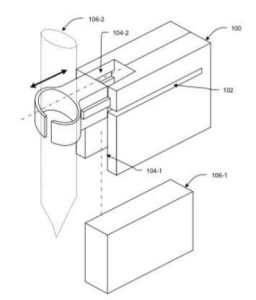

Holder for Marking Devices

A holder meticulously designed to seamlessly integrate with standard measuring tapes. This advanced holder features a sophisticated slot system, enabling secure attachment to the measuring tape while accommodating one or more marking devices. Engineered for accuracy, it allows smooth, precise marking directly on the surface being measured. Equipped with wheels for facilitated movement, an integrated processor for automated operation.

- The marking tool holder, as shown in the diagram, is Note 100. Using the central slot shown by notation 102, the holder will be attached to the measuring tape.

- The holder slides onto the tape with ease because of its application. In addition, the central slot features a self-locking mechanism.

- For projection purposes, the slot provided in Notation 104-1 can be utilized to attach chalk to a holder.

- Notation 104-2 offers a slot for attaching a clip-in holder that can accommodate a pen, pencil, marker, or laser, as shown in notation 106-2

For more details about technology: Click Here

Patent Application Number: 20232100292

Nextgen Hybrid Electric Drive System represented by NextGen Tech Initiatives Pvt Ltd

The subject technology, NextGen Hybrid Electric Drive System, is a revolutionary technology poised to redefine sustainable mobility. With its higher fuel efficiency and reduced emissions, it not only offers environmental benefits but also addresses consumer concerns with its plug-in hybrid design, eliminating range anxiety. Its adaptability for existing vehicles, coupled with its low cost and ease of implementation, makes it an economically viable solution with immense potential, especially if supported by government policies and OEM initiatives. This system boasts dual powertrain flexibility, seamlessly integrating electric and internal combustion engines while incorporating regenerative braking for energy recovery. By increasing early adoption of plug-in hybrid electric vehicles (PHEVs), it becomes a game-changing catalyst for sustainable mobility. Moreover, its industry-inclusive approach, agnostic to fuels used in internal combustion engines, ensures compatibility across a wide range of vehicles, making it a versatile and impactful solution for the future of transportation.

Abstract

Components of the Hybrid Electric Drive System:

1. Electric Drive: This consists of an electric motor, controller and battery system.

2. Epicyclic Gear System: An epicyclic gear system, also known as a planetary gear system, is a type of gear arrangement where gears rotate around a central gear.

3. Propeller Shaft: This is a shaft that transmits rotational power from the hybrid system to a rear axle (for rear wheel drive) or to a front axle (for front wheel drive).

4. Internal Combustion (IC) Engine Assembly with Gearbox: This includes a traditional combustion engine along with a gearbox for controlling speed and power being given to a propeller shaft.

Configuration and Functionality:

The hybrid electric drive system is positioned between the IC engine assembly, gearbox, and the rear axle differential of the vehicle, in case of rear wheel drive; and close proximity to the final drive coming out of the IC engine, gearbox in case of the front wheel drive vehicle.

It serves a dual purpose:

1. Individual Transmission to Wheels: It allows the transmission of power individually from each power train (electric motor and IC engine) to the wheels. This means the vehicle can be powered by either the electric motor or the internal combustion engine separately.

2. Combined Transmission: It combines the power from both the electric motor and the internal combustion engine, seamlessly transmitting it to the vehicle’s wheels. This is likely for situations where additional power is needed, such as during acceleration orclimbing hills.

Power Transmission Mechanism

The power generated by both ie the IC engine and the electric drive system is transmitted to the axle(s) through the said hybrid drive system. In simpler terms, this NextGen hybrid electric drive system is a sophisticated mechanism that efficiently manages the power generated by both the electric motor and the traditional internal combustion engine, for both the front wheel as well as rear wheel drive systems. It allows the vehicle to operate on electric power alone, traditional fuel-powered engine alone, or a combination of both, depending on the driving conditions and power requirements. This kind of system is designed for optimal energy efficiency and flexibility in various driving scenarios

For more details about technology: Click Here

Patent Application Number: IB2022 / 060089

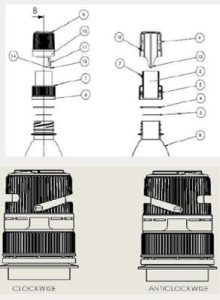

Doser Cap For Liquid Container

Unique Features

A doser cap with a self-contained moisture proof design having two movable components for housing dry powders, minitablets or granules or mixtures.

A unique cam slot and cam guide mechanism for dispensing contents into bottles for reconstitution of the contents in the form of a solution.

Novelty of the design acknowledged by International search report of WIPO.

Dispenses Mini tablets or Pellets or Granules that can result in sparkling beverages

▪Tamper evident with anti counterfeit features

▪Unit dose container

▪Easy to operate

▪Can work with re-usable water bottles

▪Adding fizz to Fast Growing flavored low alcohol content beverages

Story of Doser Caps

- STEERLife has invented the worlds best effervescent technology – EXIMIOUS.

- The effervescent granules from EXIMIOUS have applications in pharmaceuticals, nutraceuticals and also in the beverages industry.

- Effervescent granules aid creation of fizz ‘on the go’, which provides significant advantages in handling beverages.

- STEERLife and ActiveBiz have together invented a novel doser cap, which aids in carrying and releasing effervescent granules to a bottle of liquid.

For more details about technology: Click Here

Patent Application Number: PCT/IB2018/051692

Eco-kor: Innovative device to save fuel Scientific breakthrough for cooling industry

What is EcoKor

We are using a novel and patented multi-cascade for improvement in the efficiency of the refrigeration cycle. We include clever algorithms which continually optimise performance according to temperature. Ecokor is placed between the compressor and the fridge or area that needs to be cooled with advanced switching schedule decrease energy consumption and prolongs lifetime.

Eco-kor Transport

- Multi-cascade system Which allows to reduce fuel consumption And truck cooling time.

- The Eco-kor provides fuel savings of 15% -38% (depending on climate terms and kind of refrigeration truck)

Patent Application Number: IL2017/051383

For more details about technology: Click Here

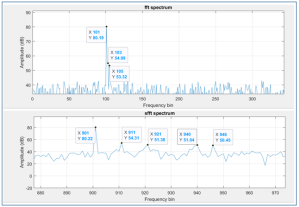

SMART FFT

SEMICONDUCTOR MARKET GROWTH

- 2021-2029

- 573.44 billion to USD 1,380.79 billion exhibiting 12.2% CAGR of the forecast term

- Increase in the consumption of consumer devices

- Key Industry players: Broadcom, Intel, and QUALCOMM to FOCUS on Developing innovative Products to Strengthen Offering

For more details about technology: Click Here